| Device Name: | Ultrafine powder spray dryer |

| Equipment type: | QFN-CX-3 (customized) |

| Equipment specifications: | 3Kg/h (support customization) |

| Test machine: | Support the test machine to do the experiment |

| Scope of application: | Powdered and granular solid products are produced in solution, emulsion, suspension and paste liquid raw materials. |

| Applicable scenarios: | Scientific research, chemical industry, food, pesticide, medicine and biological industry in Universities |

| Is it guaranteed? | Three-year National Warranty |

| Consultation telephone: | 17317246351 |

1. Equipment characteristics

2. Equipment superiority

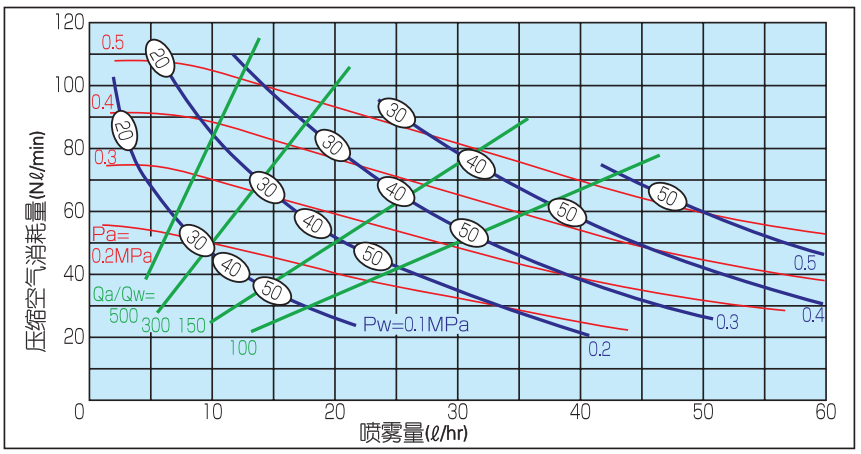

2-D Curve of QFN-PWCX-NZY8VER2018-075A Atomization System

Line reading

1 indicates the spray volume of a nozzle (l/hr).

The red line represents the compressed air PA (MPA), the blue line represents the liquid pressure, the PW (MPA), and the green line represents the QA/QW steam-water ratio.

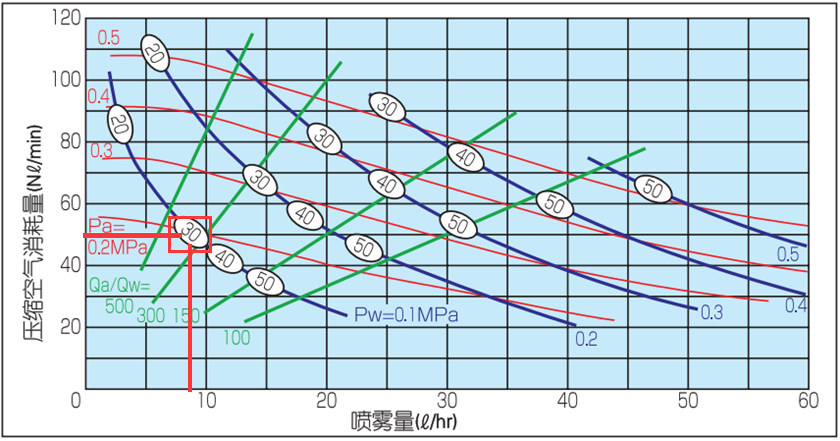

3. Measurement of 2-D Curves of 4. QFN-PWCX-NZY8VER2018-075A Atomization System by Toplephic Method

Line reading

1 indicates the spray volume of a nozzle (l/hr).

The red line represents the compressed air PA (MPA), the blue line represents the liquid pressure, the PW (MPA), and the green line represents the QA/QW steam-water ratio.

4. The number inside represents the average SAUTER particle size (micron) measured by Toplephine.

The number inside represents the average SAUTER particle size (micron) measured by Toplephine.

QFN-CX-NZY8VER2018-075A atomization system:

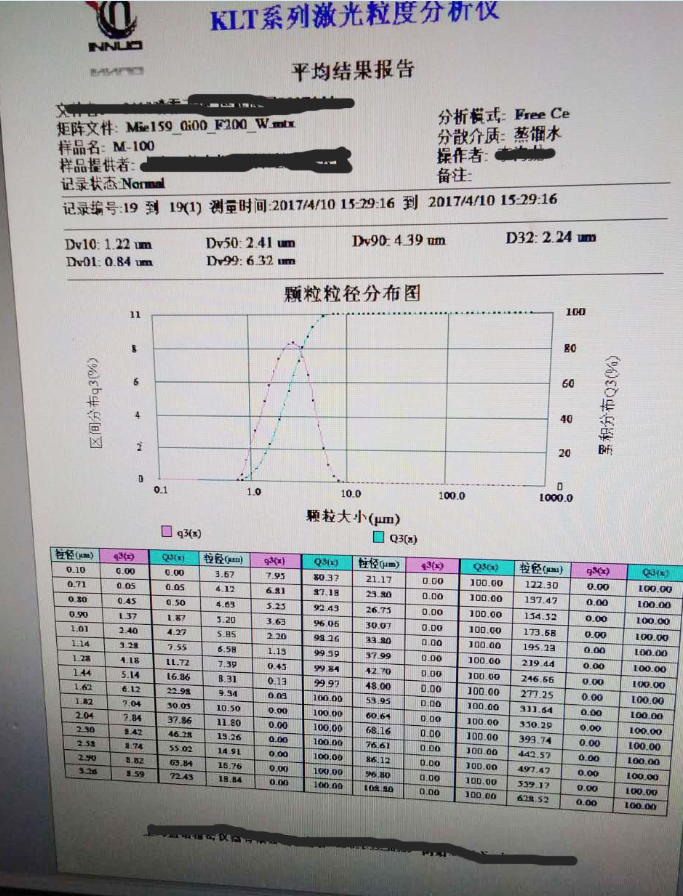

For example, if the final average dry powder size is about 3 microns, the known condition is that the solid content of the feed solution is 10%.

Then the average wet droplet size required is 3/0.1=30 micron. The liquid intake is about 8 L/hr, the compressed air needs 0.2 MPA, and the intersection point is about 30 micron.

For droplets of other sizes, first determine the treatment capacity, make a vertical axis, find the approximate size of the droplets, and then find the intersection point to find the compressed air pressure.

Note: According to the influence parameters of density and viscosity of materials on droplets, the final average diameter of droplets should be 30 [-27,33]

5.Device parameters

|

Ultrafine powder spray dryer |

QFN -CX-3 |

QFN -CX-Five |

QFN -CX-Ten |

|

Water evaporation |

3Kg/h |

5Kg/h |

10Kg/h |

|

Minimum feed rate |

80ml |

80ml |

120ml |

|

Drying chamber diameter (mm) |

¢600 |

¢800 |

¢1200 |

|

Height of drying tower (mm) |

¢800 |

¢800 |

¢1500 |

|

Atomization structure |

Single-hole misaligned atomization structure (QFN-CX-NZY8VER2018-1A) |

||

|

Electric control system |

QFN-CX-ES-VER2018-1A |

||

|

Maximum intake temperature (Celsius) |

Two hundred and sixty |

||

|

Standards for main electronic control accessories (including PLC, analog module, touch screen) (optional) |

Dimension Control Module (Standard)Delta Control Module_German Siemens Control Module |

||

|

Selection Standard for Electronic Control Auxiliary Parts (Contactors, etc.) (Optional) |

Zhengtai (Standard) Delicious Schneider Others________ |

||

|

Contact with material (optional) |

"9745; SUS304 (26631;" 20934; 160;"160;" 160;"160;" SUS316 "160;" 1600;"D"20854;"20182;uses |

||

|

Tail gas reuse, energy saving more than 30% (optional) |

Non-assembly (Standard) Assembly |

||

|

Atomizing nozzle (whether diamond coating is used) |

SUS304 (Standard) SUS316 (Standard) SiC (Standard) Diamond |

||

|

Equipment warranty |

_1 year (standard, above need to charge a certain maintenance fee)2 years_3 years |

||

|

Heater capacity |

6Kw |

15Kw |

25Kw |

|

Blower [power (kw), air volume (m/min)] |

nothing |

nothing |

[0.25,9.5] |

|

Induced draft fan [power (kw), air volume (m/h)] |

[1.5,250] |

[2.2,300] |

[2.2,300] |

|

Compressor [Power (kw), Air Volume (L/min)] |

[0.58,108] |

[1.5,250] |

[1.5,250] |

|

Electricity (installed capacity) |

8Kw |

30Kw |

40Kw |

|

Thermal insulation material |

50mm Glass Fiber Thermal Insulation Cotton |

50mm Glass Fiber Thermal Insulation Cotton |

50mm Glass Fiber Thermal Insulation Cotton |

|

_Pulse bag filter (optional) |

Polytetrafluoro Film Coating Material |

||

|

4 only |

4 only |

9 Only |

|

|

Profile Size (mm) (L X W X H) |

1600×1400×1800 |

2200×1600×2200 |

2600×1200×2500 |

|

Installation Weight (Reference) |

200Kg |

450Kg |

1000Kg |

|

Power Supply |

380V/-3(Relevant voltage can be customized according to different national standards) |

Note 1: Water evaporation to air temperature 250 C,.

2: If you need more evaporation equipment, please make an online inquiry or call our company.

Tel: 17317246351

Mailbox: sales@qfn17.com

URL: http://www.carbonblack.org.cn

Address: Shanghai fengxian canal north road no. 1185